GANA Machinery Co., Ltd. has maked and sold only rebar processing machines for 20years

The Fourth Cutting and Bending of ReBar Revolution, GANA Machinery Co., Ltd. are going to with you.

WG12E-2

Feature

- It is cost-effective and has excellent processing performance

(processing 10mm x 2pcs, 13mm x 1pcs).

- It has automatic cutting and bending system by CNC control.

- Data entry and automatic control by touch panel

- It is advantageous for small size, small amount of and various kinds of

components processing.

- Feeding motor is installed, so you can easily put in the rebar.

- Minimized failure rate with continuous improvement and update.

Specification

WG12E-2 Specification

|

Single strand diameter |

5~13mm |

|

Double strand diameter |

5~10mm |

|

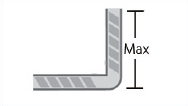

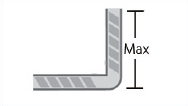

Maximum bening angle |

180° |

|

Bending direction |

Bi-direction |

|

Maximum pulling speed |

110m/min |

|

Maximum bening speed |

1200°/sec |

|

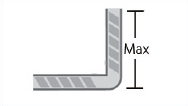

Maximum diagonal size |

1,670mm |

|

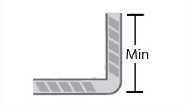

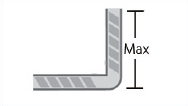

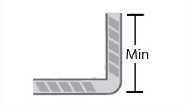

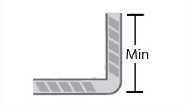

Minimum length of square stirrup side |

100mm |

|

Average electrical power consumption |

5kW |

WG3D12

Feature

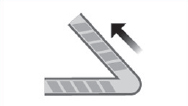

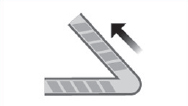

- It can process 3D shapes (e.g. chicken feet shape, etc.).

- It is cost-effective and has excellent processing performance

(processing 10mm x 2pcs, 13mm x 1pcs).

- Data entry and automatic control by touch panel

- It has automatic cutting and bending system by CNC control

- It is advantageous for small size, small amount of and various kinds of

components processing.

- Feeding motor is installed, so you can easily put in the rebar.

- Minimized failure rate with continuous improvement and update.

Specification

WG3D12 Specification

|

Single strand diameter |

5~13mm |

|

Double strand diameter |

5~10mm |

|

Maximum bening angle |

180° |

|

Bending direction |

3D(상/하/좌/우) |

|

Maximum pulling speed |

110m/min |

|

Maximum bening speed |

1200°/sec |

| 300°/sec(3D) |

|

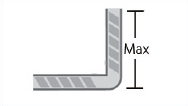

Maximum diagonal size |

1,670mm |

|

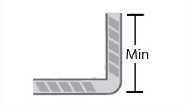

Minimum length of square stirrup side |

100mm |

|

Average electrical power consumption |

6kW |

WG13B

Feature

- The shape of the work piece is good by installing

the long type guide.

- The fine linear bolt is exposed externally, allowing for linear

alignment during processing.

- Data entry and automatic control by touch panel

- It has automatic cutting and bending system by CNC control.

- It is advantageous for small size, small amount of and various kinds of

components processing.

- Feeding motor is installed, so you can easily put in the rebar.

- Minimized failure rate with continuous improvement and update.

Specification

WG13B Specification

|

Single strand diameter |

5~13mm |

|

Double strand diameter |

5~10mm |

|

Maximum bening angle |

180° |

|

Bending direction |

쌍방(상/하) |

|

Maximum pulling speed |

110m/min |

|

Maximum bening speed |

1200°/sec |

|

Maximum diagonal size |

1,540mm |

|

Minimum length of square stirrup side |

160mm |

|

Minimum length of square stirrup side |

6kW |

WG16B-2

Feature

- It is cost-effective and has excellent processing performance

(processing 10mm x 2pcs, 13mm x 2pcs, 16mm x 1pcs).

- It has automatic cutting and bending system by CNC control.

- Data entry and automatic control by touch panel

- It is advantageous for small size, small amount of and various kinds of

components processing.

- Feeding motor is installed, so you can easily put in the rebar.

- Minimized failure rate with continuous improvement and update.

Specification

WG16B-2 Specification

|

Single strand diameter |

6~16mm |

|

Double strand diameter |

6~13mm |

|

Maximum bening angle |

180° |

|

Bending direction |

쌍방(상/하) |

|

Maximum pulling speed |

110m/min |

|

Maximum bening speed |

1200°/sec |

|

Maximum diagonal size |

2,450mm |

|

Minimum length of square stirrup side |

150mm |

|

Average electrical power consumption |

10kW |